ABOUT CRILD

Shenzhen Child Technology Co.,Ltd

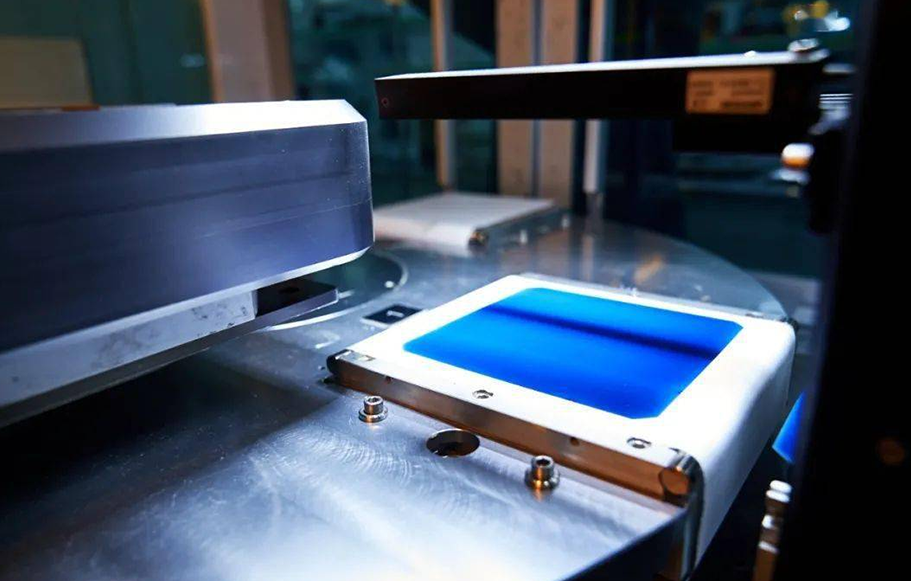

Shenzhen Changya Technology Co., Ltd. was founded in 2007. It is a national high-tech enterprise specializing in R & D, production, sales and after-sales service. It is a manufacturer of integrated automatic production lines and intelligent equipment manufacturers using machine vision systems.

Industry R & D experience

Industry R & D experience

PRODUCT CENTER Products

We have strong technical force in the field of vision systems such as image acquisition and processing, image pattern recognition, image processing and algorithms, and have accumulated a lot of successful experience and have completely independent intellectual property rights.

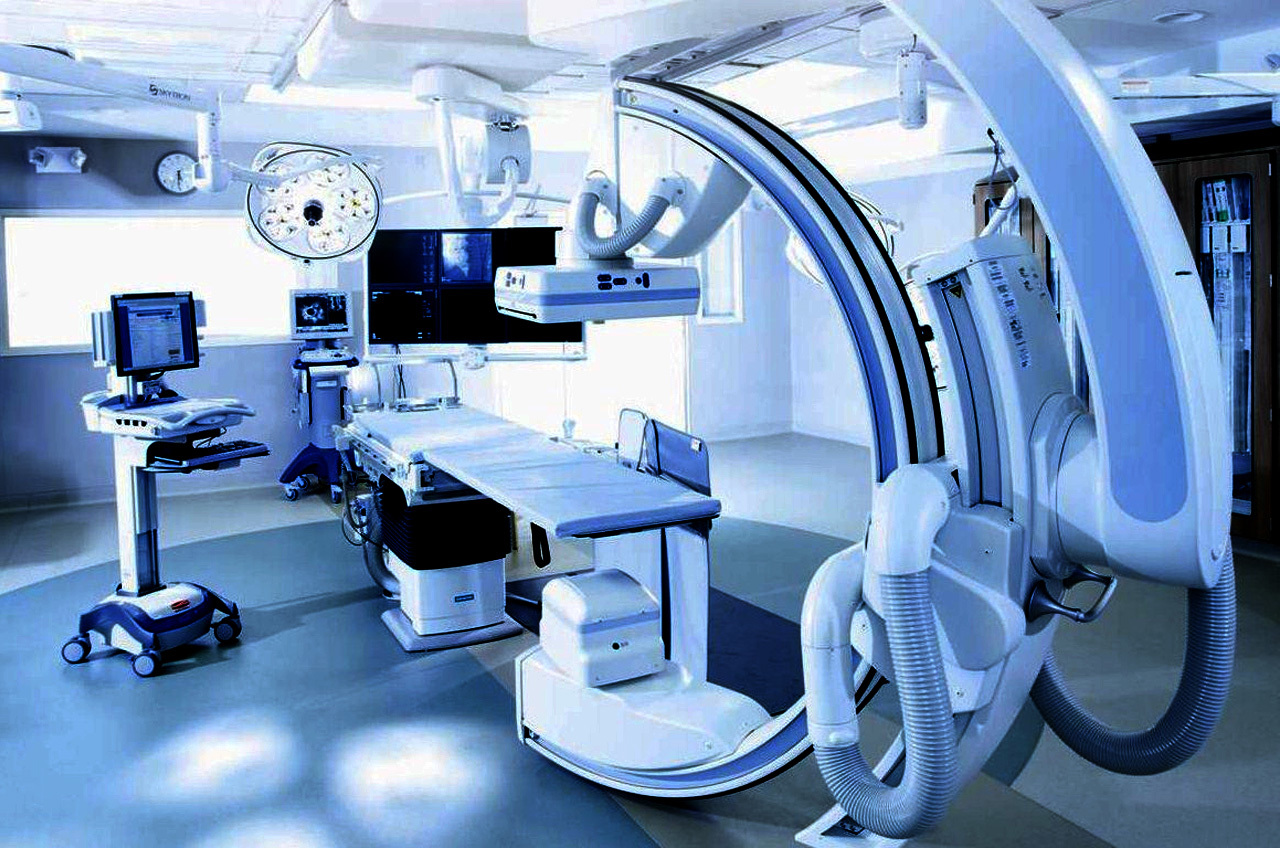

APPLICATION Application areas

PARTNERS Partners

The user's response is the spur to our company, and always adhere to the principles of "quality assurance", "user experience", "quality service" and "sincerity and trust".

NEWS News

We have strong technical force in the field of vision systems such as image acquisition and processing, image pattern recognition, image processing and algorithms, and have accumulated a lot of successful experience and have completely independent intellectual property rights.

Contact Us

Shenzhen Child Technology Co.,Ltd

Fax: 86 0755 29588226

Q:1147800975

Address: 3rd Floor, Building 6, No.4 Industrial Zone, Xitian Community, Gongming Town, Guangming New District, Shenzhen

Huizhou Changya Technology Co., Ltd

Address: Building 6, Yinong Science and Technology Village Revitalization Science and Technology Industry Demonstration Park, No.3 Xinhua Avenue, Chen Jiang Street, Zhongkai High-tech Zone, Huizhou City

Shenzhen Changya Technology Co., Ltd. Jiangsu Branch

Mobile phone: 13823324319 Mr. Zou Q Q:1842040671

Address: Zhengtailong International Industry and Trade City, 1288 Chengbei Middle Road, Kunshan City, Suzhou City No. 3088, Area C, Pavilion 5

Sincerely welcome the community to visit the group, and seek common development, create brilliant!

Follow Changya

Add WeChat

Copyright©2023 All rights reserved of Shenzhen Changya Technology Co., Ltd.SEO

Powered by www.300.cn

Screen Flip Component Settings Panel

容器ID名称:#c_grid-1698807741246

关闭翻屏分辨率:768