Products

- Product Description

-

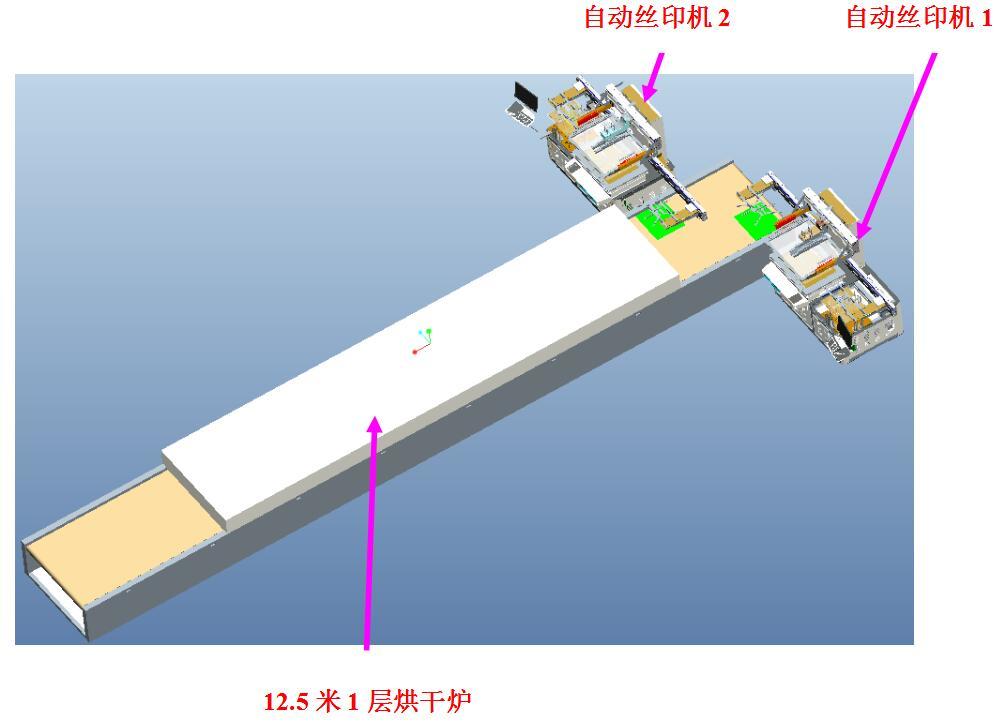

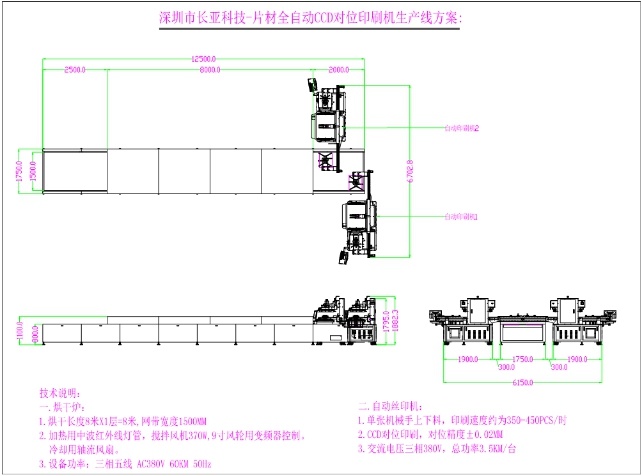

1. Machine Description

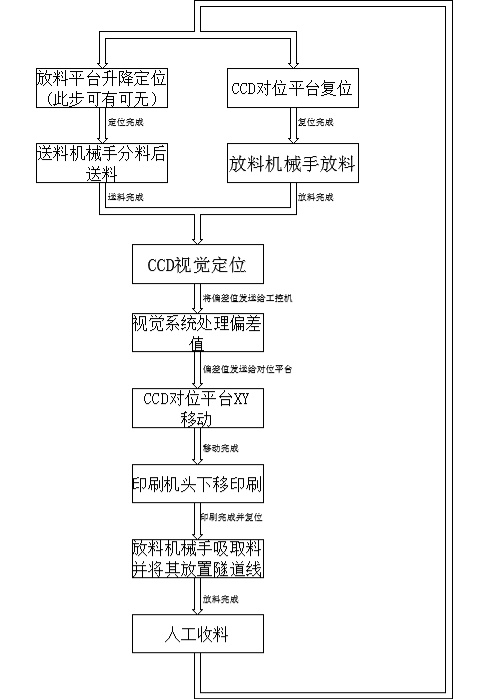

(The whole set of equipment design concept using CCD visual positioning system, CCD alignment platform XY θ precise mobile positioning function automatic feeding → automatic printing → automatic blanking → automatic baking → automatic material collection to achieve fully automated operations)

2. machine workflow

Simple diagram of 3. machine

4. machine characteristics1. The printing machine base adopts the whole fine plate processing structure is stable, the operation is light and without jitter.

2. The screen clamping frame adopts manual and pneumatic automatic clamping design, which is easy to operate.

3. Printing using Fuji servo motor, with linear guide guide, fast and stable, accurate positioning.

4. man-machine interface control button switch, can set a variety of functions and parameters, easy to operate.

5. Safety pressure plate, photoelectric switch, emergency stop button, careful safety protection.

6.CCD automatic positioning printing, according to the size of the material can automatically adjust the field of view of the CCD.

7.CCD automatically calculates the spatial position of the material and the screen plate according to the Mark point on the material, and instructs the motor motion control and adjustment platform X, Y and θ rotation to automatically position and print

8. Printing using cleaning roller dust.

9. Manipulator automatic loading and unloading, high efficiency, high quality yield.

10. The machine is integrated with an anti-dripping ink device.

10. No material shutdown alarm, real-time monitoring of machine production information, etc;

5. important accessories are configured as follows

Accessory Name

Accessories Brand

Origin of accessories

Guide/Slider

Yintai

Taiwan

screw rod

GTE

Taiwan

CCD camera

Yingmei Jing

Germany

industrial computer

Ling Hua

Taiwan

Drive/Motor

Fuji

Japan

Cylinder

Yadke

Taiwan

Solenoid valve

Yadke

Taiwan

Motherboard

CY

Independent research and development

6. machine specification parameters

Specifications

Parameters

Printing table size

700X1000mm

Maximum printing area

500X 600mm with shooting function (550X700MM without shooting function)

Minimum printing area

250X250mm

Print thickness

0.05-2 mm

Table Level Accuracy

±0.05 mm

Mesa suction aperture size

¢1.0 mm

Spacing dimension of suction holes on countertop

15X15 mm

Scratch printing method

Single Scraper Printing Single Lift Net

CCD image taking range

Two mark points within 130-500mm (according to customer requirements)

CCD lens field of view

12X9 mm

Number of Apair Cameras

4

Image alignment accuracy

±0.005 mm

Integrated accuracy

±0.02 mm

counterpoint integration time

<1ses

Maximum framed size

800X1150 mm

Screen frame thickness

30-40 mm

Maximum distance between table top and net frame lifting

350 mm

Table height

960±20 mm

Scraper printing

1-6kg

Clearance for lifting net

0-10mm (manual)

Printing screen and table spacing

0-15mm (HMI setting)

Printing stroke

0-800mm (HMI setting)

Scraper inclination

±40°

Machine Dimensions

2200X1460X1882mm (excluding the loading and unloading dimensions of the manipulator)

Machine power supply

380V、50HZ

Machine weight

1600KG

Related Products

online message