Products

- Product Description

-

[Machine description]]

Fully automatic mechanical punching machine absorbs the advantages of various automatic punching machines at home and abroad, and is carefully designed in combination with the needs of our country's production. adoptedWINDOWS XPoperating system,PCIBus high-performance servo control card,PCIThe control system is composed of high-performance image acquisition card and high-resolution encoder servo motor.

The mechanical structure adopts high precision grinding ball screw andLMThe sliding track ensures mechanical positioning accuracy. This equipment is suitable for mass production and plate punching more dense products. Manual feeding, manipulator automatic feeding, automatic machine mechanized feeding, punching. Greatly improve the production efficiency.

[refer number]]

OneProcessing the image

1.Target material:FPC, mobile phone panel, film, etc.

2.Working dimensions:Max 600(L)x300(W)mm

3.Workpiece thickness: depending on the material and punch diameter

IIProcessing capacity

1Punching accuracy: ±0.02mm

22. Punching diameter: φ1.0~5.0mm

3Punching speed:0.35Seconds/Hole

ThreePunches:

1Drive mode: pneumatic drive

2Installation method: lower die fixed, upper die action, rubber return

FourWorkbench

1Clamping method: paste type

2Action mode of material support plate: pneumatic drive up and down

3Workpiece tensioning and clamping bracket: according to the size of workpieceXAxial adjustment, handle locking

FiveControl System

1Operating system:Windows XP.

2Display: 8InchesTFT LCD(4/3).

3Running program:CrildHave their own intellectual property control software.

42. Product operation data: obtained according to physical manual operation learning or material path software.

SixImage Processing:

1.Camera:600Line1/3InchesCCD.

2.Field of vision:9*11mm

3.Processing method: Gray mode measurement

4.Lighting mode: high brightnessLEDColorful transmission and reflection

7. use environment

1Temperature:20~30Degree

2Humidity: air conditioning

3Size:1700(L)×1000(W)×1100(H)cm

4Weight: approx.780Kg

5Power supply:AC210-240V 2KVA

6Air pressure:0.5~0.8MPa

[Features]]

☆Large processing material area

☆Manual feeding, manipulator automatic feeding, automatic machine mechanized feeding, punching. Greatly improve the production efficiency.

☆Reduce the friction between personnel and the machine surface when moving the plate, and reduce the bad law.

☆To avoid the leakage phenomenon caused by human factors, the hole position can not be identified by the manipulator directly fill the hole.

☆ Simple operation:Embedded XP system, humanized design, can be customized settings, easy to operate, simple and intuitive.

☆ High accuracy: the camera automatically finds the map within the recognition range, computer analysis, and control the movement.

☆ Fast speed: the camera has a short reflection time, and the punching of the graphic position can be controlled as soon as the graphic is found.

☆ Powerful: sampling map can be saved, and then can be directly called. Computer system, software can be upgraded in real time.

☆ Quality assurance: pressure regulating valve, cylinder, solenoid valve, track and other major components are imported to ensure service life.

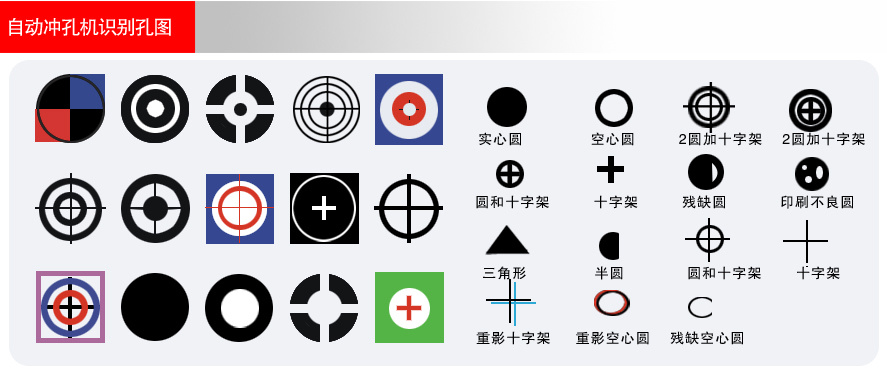

☆ High recognition:Can automatically identify a variety of materials on the circular figure, special printing materials,Reflective mirror material,Cross circle, printing is not clear, incomplete circle (including semicircle) can also be accurate and automaticPunching, greatly improving the production efficiency.

Related Products

online message