Products

- Product Description

-

[Machine description]]

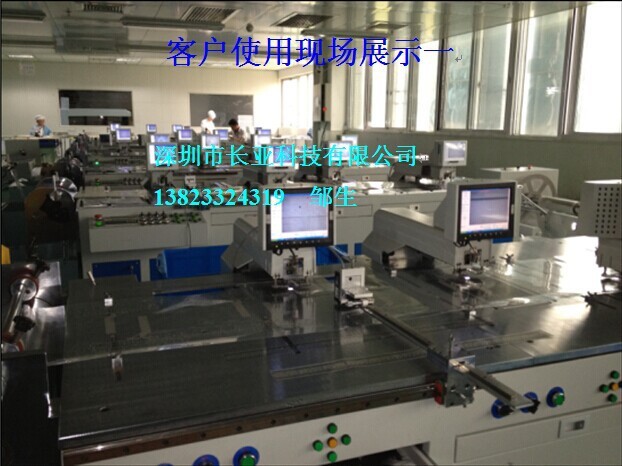

The full-automatic roll-to-roll punching machine is an automatic equipment that integrates automatic feeding, automatic feeding, automatic punching and automatic cutting for roll printing products. This product adopts industrial computer control, servo motor transmission, high-definitionCCDImage positioning of a high-tech automation equipment. The realization of automatic roll-to-roll automatic positioning punching machine, the real sense of the realization of unmanned operation, to meet the needs of customers in mass production, thereby significantly reducing costs and improve production efficiency.

[Main referencenumber]]

1.Punching diameter Φ1-Φ5.0MM (support for customization)

2.Identification circle diameter Φ1-Φ6.0MM(Can be marked with "cross circle")

3.Punching thickness:0.10mm-1mm (Depending on the material)

4.Punching speed: 1S/4 holes

5.Machining accuracy:≦±0.015mm

6The largest.Processing width:600mm

7. The maximum processing range of the machine head: the width of the hole distance is less480MM

8. Maximum momentum:3000N

9. work Consumption: 1.6-2.0KW

10. Working voltage:AC220V-240V

11.Working gasPressure:2Mpa

12. Machine appearance:3000MM *1200MM *1500MM

12. Machine net weight:2000KG

13.Use RingEnvironment:Air conditioning

14. Light source: infrared transmission, infrared reflection

15. Feeding partyType:NCServo feeding

Patent name: automatic roll to roll punching machine, patent number:201220235045.3

application field]

Electronic,Placard,Packaging,Printing and other industries positioning hole processing such:FPCRoll, film roll,PETRoll material, adhesive roll material, film roll material, etc.

[Special point]]

☆.Automatic light sensing Material: As long as the processed material is outside the infrared sensing range, the feeder will automatically discharge the material to provide the material length required for the next feeding.

☆.Automatic roller guide frame: the product is fixed with the surrounding guide block to ensure that the product always maintains the same direction.

☆.Dust removal and anti-static function: dust removal and anti-static rollers are installed on the work surface, which can remove dust and static electricity on the surface of the product.

☆.Orientation Fast: The work surface is equipped with a directional positioning function to ensure that the product does not deviate from the material during the long-distance pulling process.

☆.CCDImage precise positioning:CCDIndustrial camera precise positioning, to ensure accurate positioning of the product, there will be no partial hole leakage phenomenon.

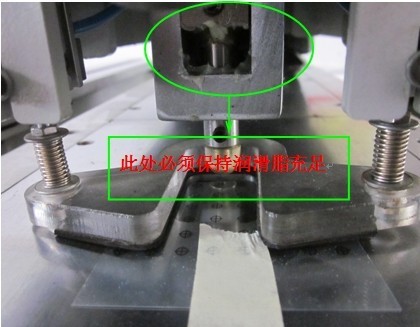

☆.punch Hole Mold Tools: The punching die adopts imported high-speed steel and fine grinding and vacuum heat treatment to ensure the accuracy and service life of the die.

☆.Man-machine interface display: the punching machine adopts man-machine interface display, which can watch the punching live synchronously.

☆. N CServo Feeding:NCServo feeder adopts imported Japanese Yaskawa servo feeder,PLCprogramming, can be set30Step distance, each feeding accuracy to ensure0.01MM.

☆.Light-sensitive color tracking locator: Light-sensitive color tracking can control four punching heads to simultaneously punch holes to ensure consistency.

☆.Automatic cutting function: product positioning hole processingOKAfter that, the cutting knife can passPLCAutomatic signal cutting.

☆.Put Material Speed Degree: can be adjusted at will, starting frequency from0Start to slowly rise to run to avoid starting too fast, causing scratches on the surface of the material.

☆.punch Hole Speed Degree: This equipment is independently developed by our company.CYSeries software, high-speed stable motor, high-computing industrial computer, punching speed up1Seconds/4Hole

[standard accessories]]

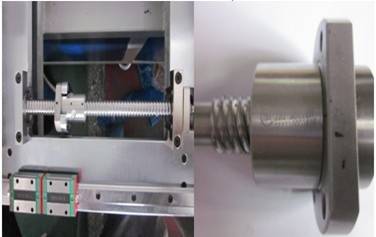

screw rod: Imported TBI

Guide rail: Silver

Cylinder:Yadke

Solenoid valve:Yadke

Motor/Drive:Xinnong

[Advantage]]

Related Products

online message